The grand event of the HFC guang Expo on the first day丨Empowering the future of optical communication with heat management innovation.

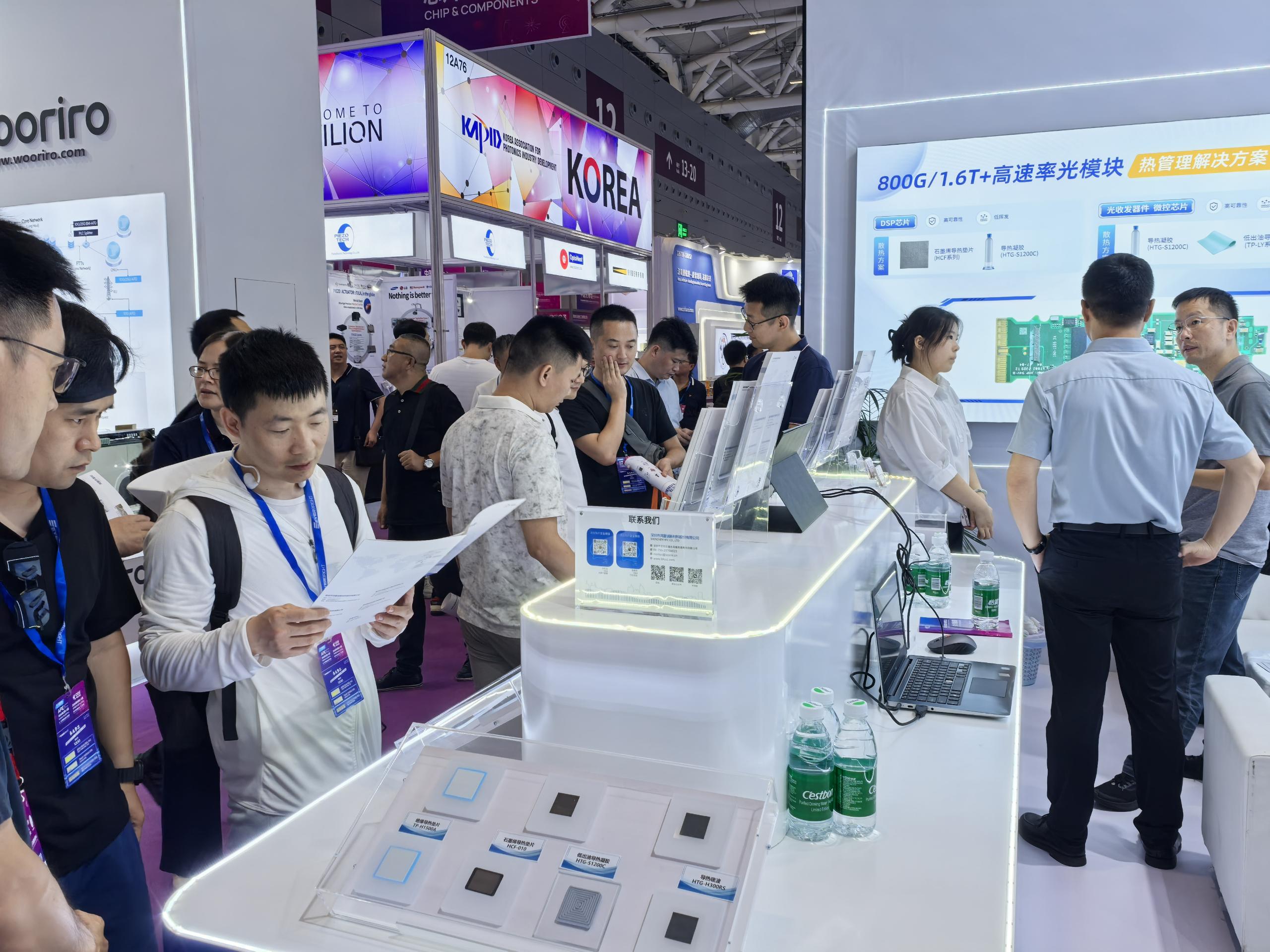

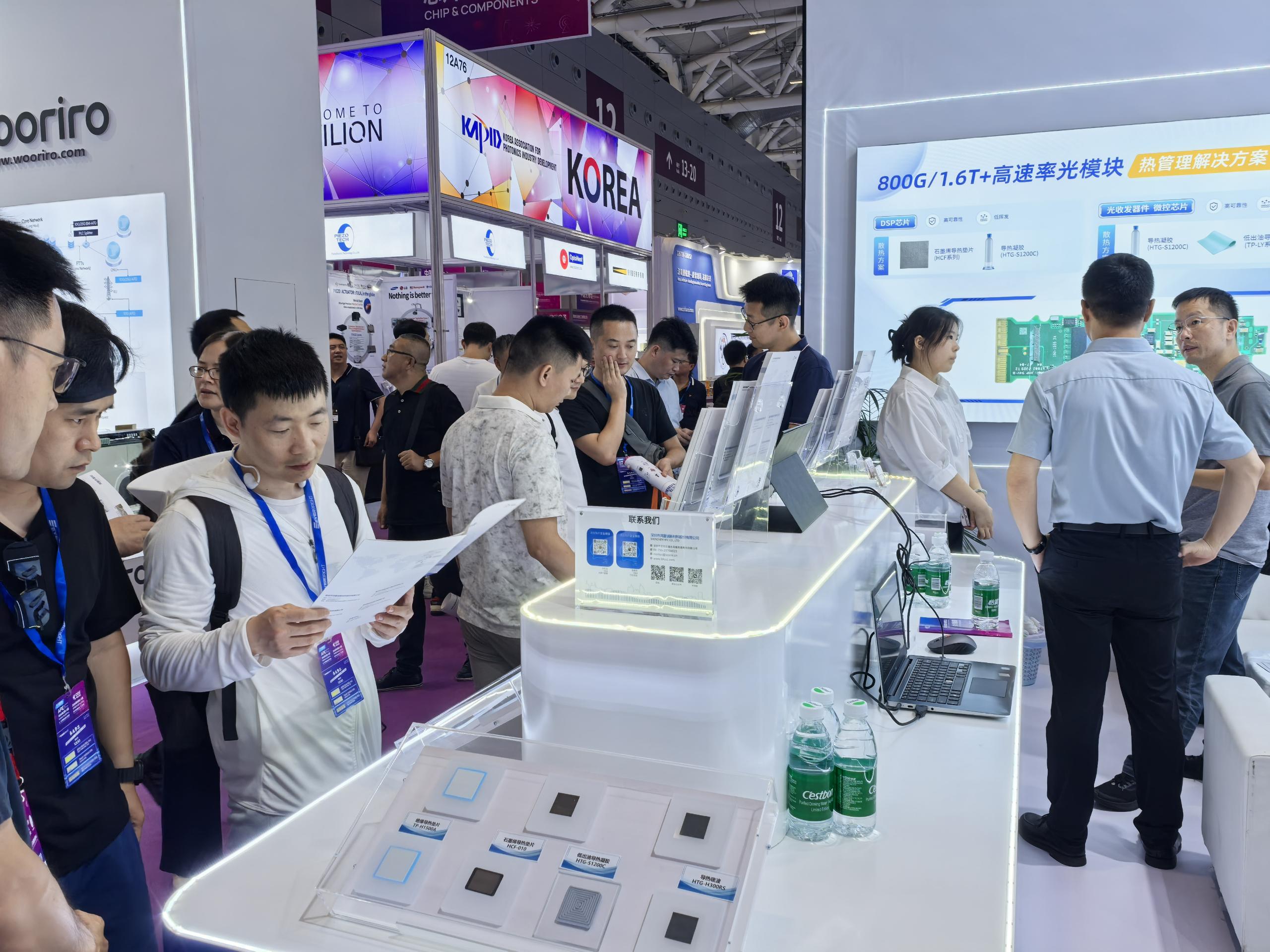

On-site coverage: Crowds are surging

On September 10th, the 26th China International Optoelectronic Exposition (CIOE2025) grandly opened at the Shenzhen International Convention and Exhibition Center. As the world’s largest optoelectronic industry event, this exhibition gathered over 3,800 enterprises and 160,000 professional attendees.

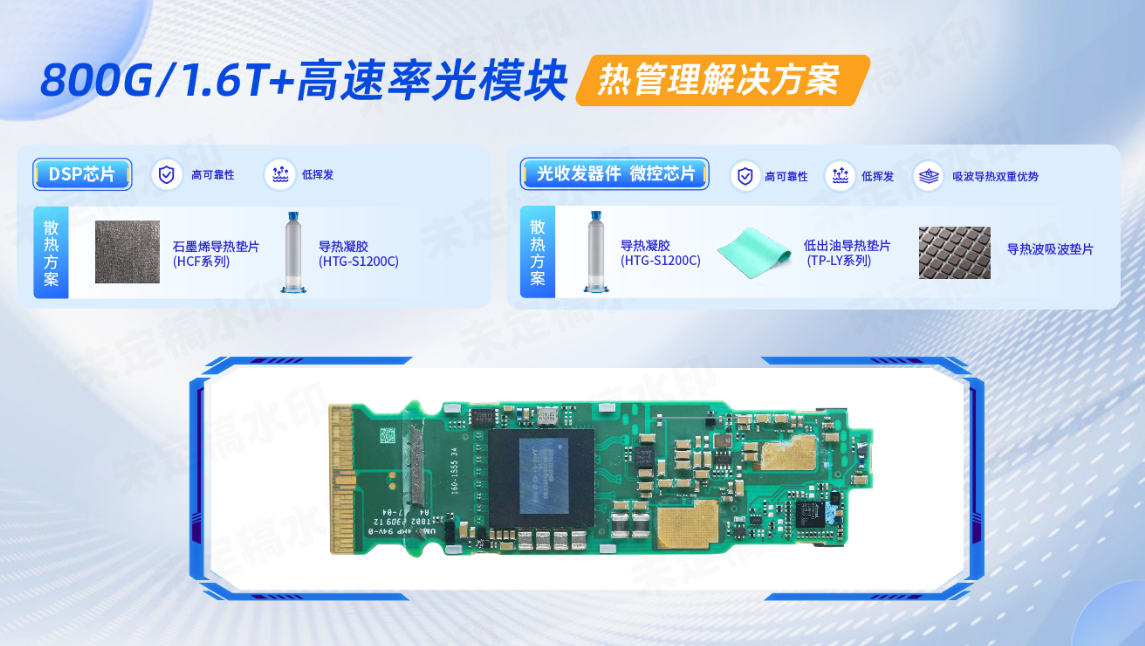

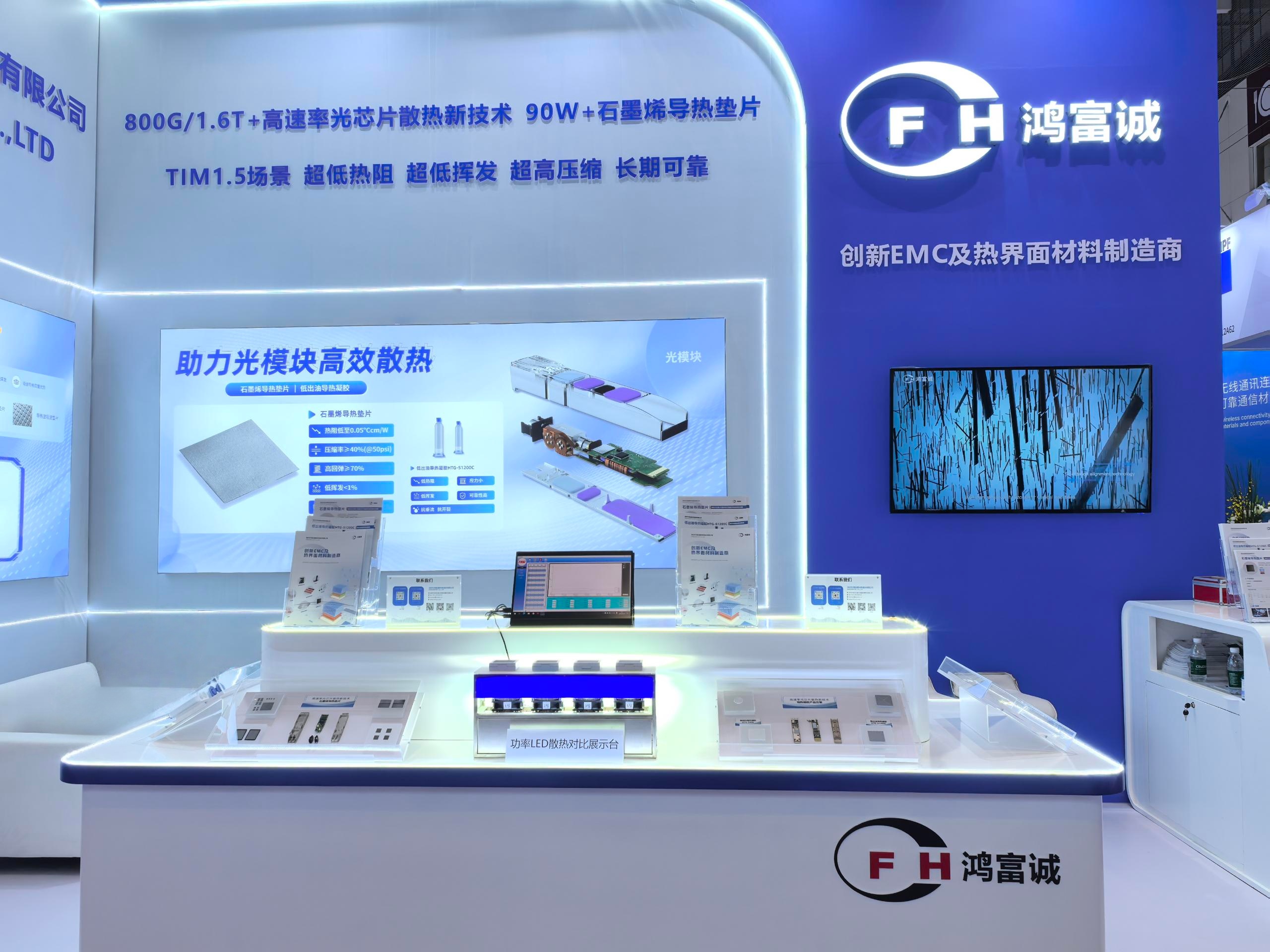

Hfc released a full range of optical module thermal management solutions, covering speeds from 400G to 1.6T, utilizing innovative thermal management technology to support the evolution of high-speed interconnection, becoming the focal point of the exhibition on the first day.

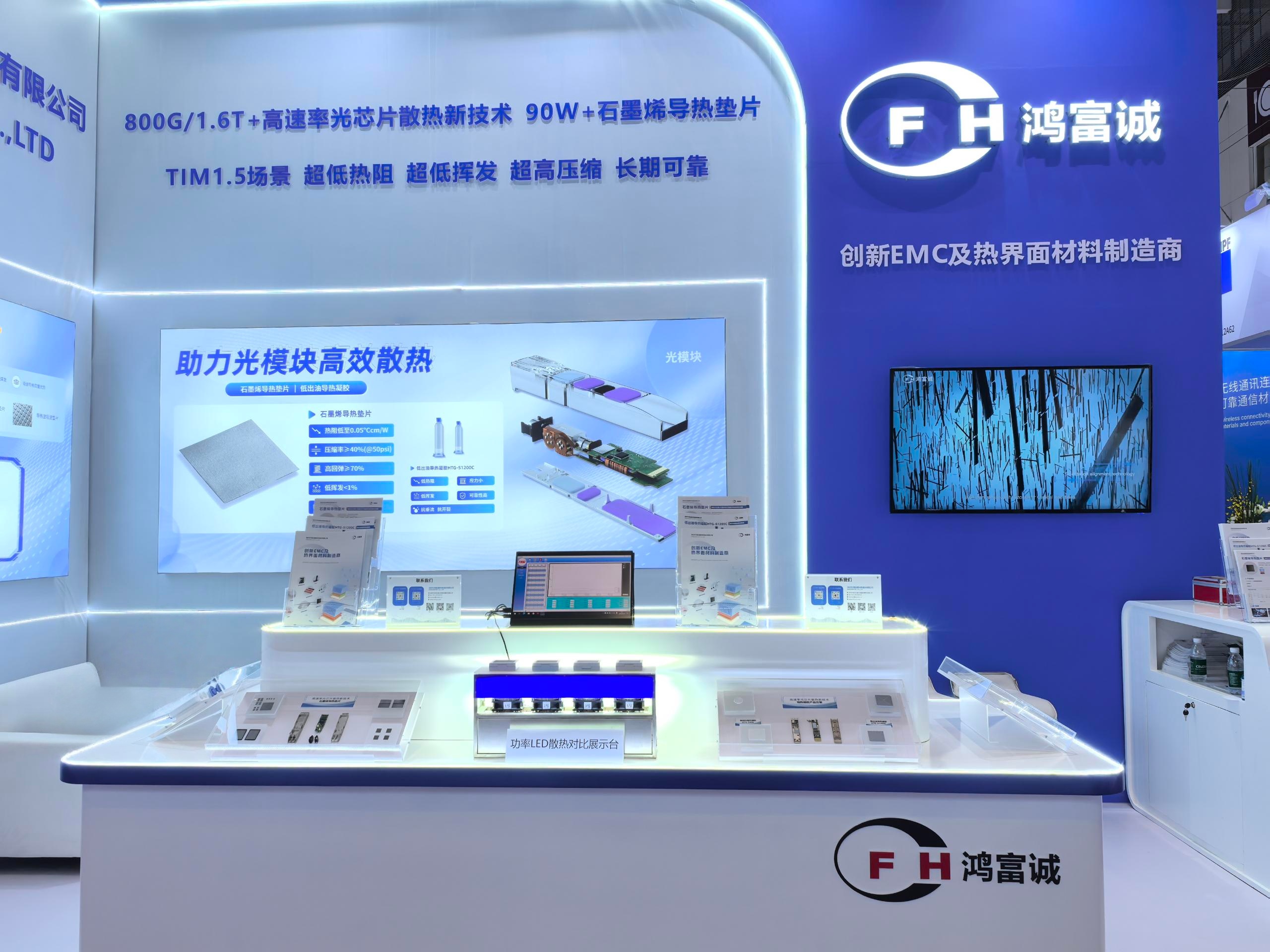

One-stop product matrix to accurately

meet the industry’s heat dissipation challenges

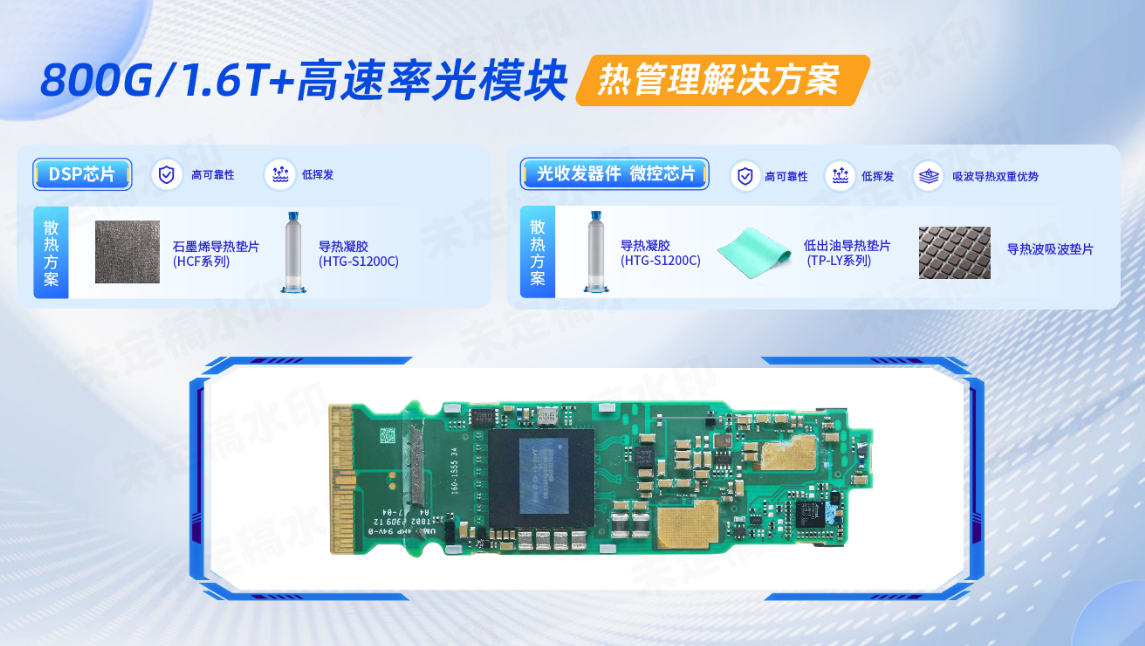

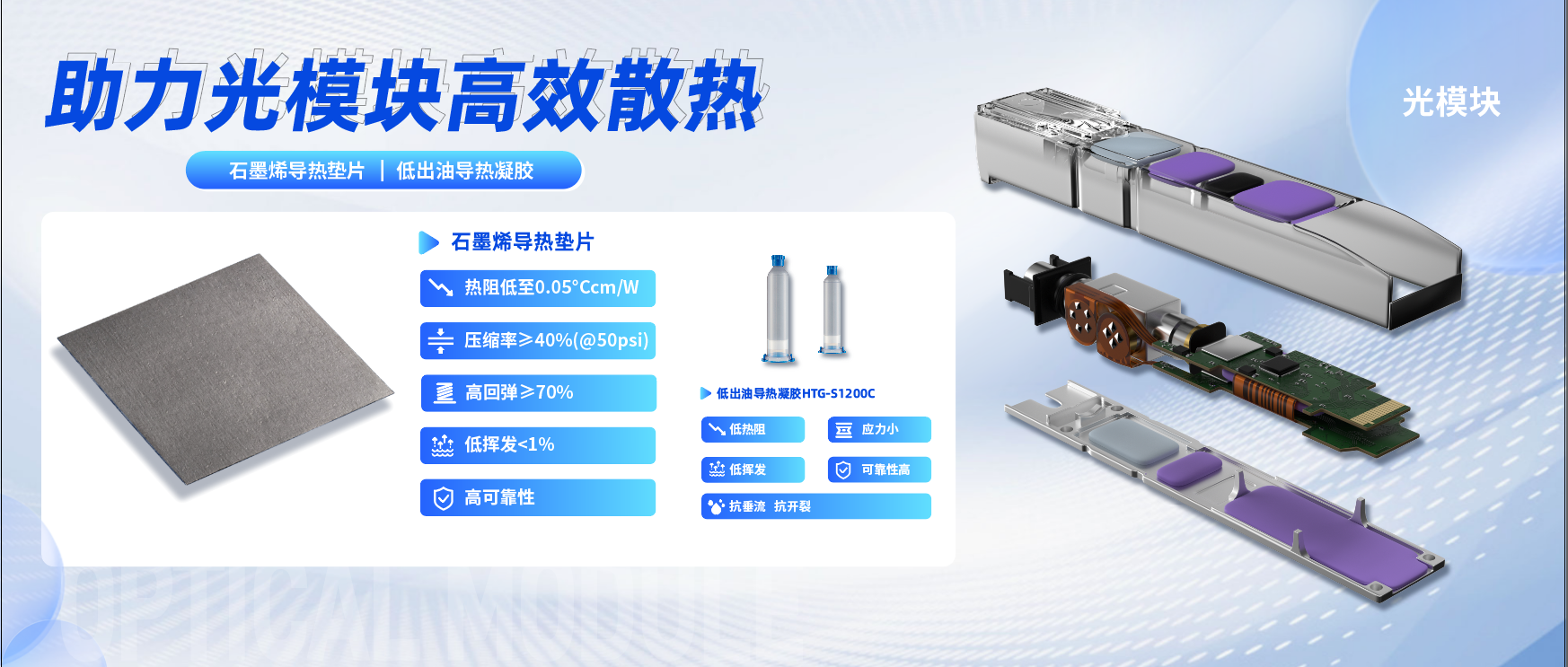

With the optical communication industry evolving towards 400G, 800G, and 1.6T high speeds, equipment power consumption and heat density have surged dramatically, making heat dissipation a key bottleneck affecting performance reliability.

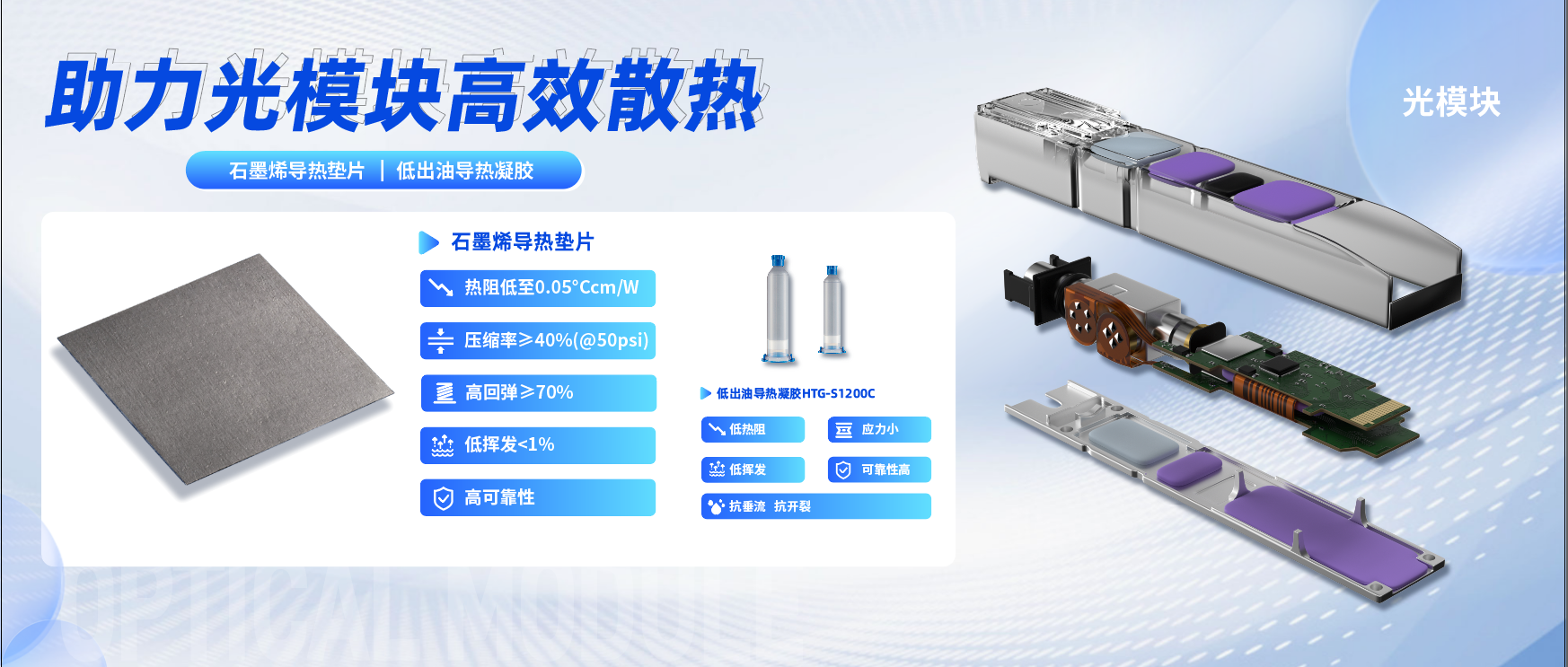

HFC relies on its profound material research and development foundation to launch a diversified matrix of thermal management products, including high-performance thermal pads, gels, and oriented graphene thermal pads, dedicated to providing comprehensive heat dissipation solutions for optical modules from the chip level to the system level.

This series of products features high thermal conductivity, low thermal resistance, and excellent reliability, which can significantly enhance the heat dissipation efficiency of equipment, ensure data transmission rates and long-term operational stability, and help customers cope with the high-density heat dissipation needs of future data centers and communication networks.

Empowering the future of optical communication

with innovative thermal management

HFC takes industry-leading thermal management technology as its core driving force, injecting new momentum into the rapid development of the optical communication industry through continuous material innovation and process breakthroughs, assisting customers in accurately optimizing ‘thermal efficiency’ in the era of high-speed connectivity, and achieving a dual enhancement of product performance and market competitiveness.