◆ Good thermal conductivity, available in options ranging from 2.0 to 8.0 W/m·K.

◆ Soft and elastic after curing, maintaining the required thickness and providing shock absorption.

◆ High electrical insulation, with dielectric strength up to 8 kV/mm.

◆ Excellent flame resistance, achieving a UL94 V-0 rating.

◆ Curing time adjustable based on temperature.

◆ Two-component structure for easy storage.

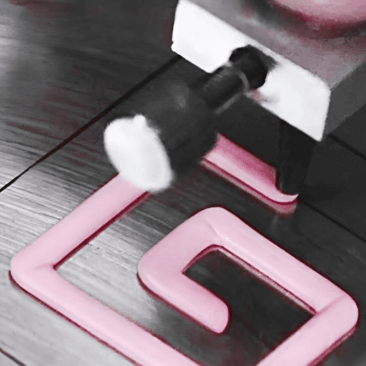

◆ Can be precisely controlled for thickness and shape using automated equipment.

◆ Complies with RoHS, Halogen-Free, and REACH environmental and safety standards.

【Applications】

◆ CPUs and GPUs

◆ Power Supply Units (PSUs)

◆ LED Modules

◆ Engine Control Units (ECUs)

◆ Gaming Consoles and Laptops

Properties

| Properties | Unit | SE300AB | Test Method |

|---|---|---|---|

| Thermal Conductivity | W/m·K | 3.0 | ASTM D5470 |

| Flow Rate(@50cc,90psi) | g/min | 20±5 | – |

| Color Before Curing | – | Part A: White Part B: Pink |

Visual |

| Density | g/cc | 3.0 | Helium Pycnometry |

| Mix Ratio | – | 1:1 | – |

| Color After Curing | – | Pink | Visual |

| Hardness After Curing | Shore 00 | 55±10 | ASTM D2240 |

| Tack-Free Time (@25℃) | min | 30 | – |

| Full Cure Time (@25℃) | h | 1 | – |

| Full Cure Time (@100℃) | min | 5 | – |

| Minimum Interface Thickness | mm | 0.10 | – |

| Shelf Life (@25℃) | months | 6 | – |

| Operating Temp. | ℃ | -50 ~ 150 | – |

| Dielectric Strength (@AC) | kV/mm | > 8 | ASTM D149 |

| Dielectric Constant (@1MHz) | – | 6.5 | ASTM D150 |

| Volume Resistivity | Ω·cm | >1013 | ASTM D257 |

| Coefficient of Thermal Expansion | ppm/K | 175 | ASTM E831 |

| Flame Rating | – | V-0 | UL94 |

| RoHS | – | PASS | IEC 62321 |

| Halogen | – | PASS | EN 14582 |

| REACH | – | PASS | EN 14372 |

【Storage & Transportation】

Store in a well-ventilated, cool, and dry place, away from open flames.

This product is non-toxic and should be stored and transported as a non-hazardous material.

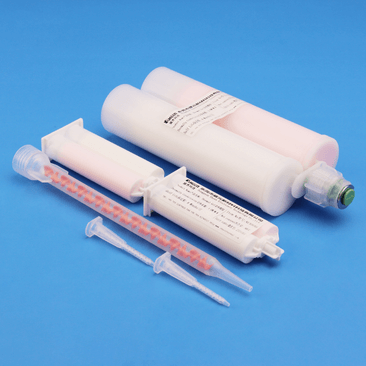

【Packaging】

● 50cc ● 400cc

【Shelf Life】

6 months